PROJECT DESCRIPTION:

Problem and Opportunity

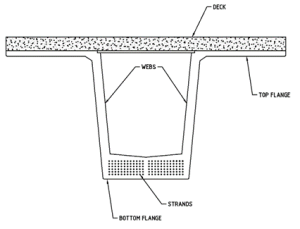

‘Teeroff’ beams are a form of precast beam widely used for bridge construction in Western Australia. The typical cross section of such beams, which is essentially a trough beam with top flanges, is shown in Figure 1. The precast beam is prestressed through strands located in the bottom flange. Note that in Figure 1, reinforcement apart from prestressing strands are not shown for clarity.

Figure 1: Typical Teeroff Section (number of strands shown indicatively only)

An in-situ poured deck slab, which is added to the top of the precast beams after placement of the beams on the supporting structures, results in the final beam section configuration where the deck slab and the Teeroff beam act compositely. For bridges with large spans, the depths of Teeroff beams can be greater than 2m with bottom flange widths exceeding 1.5m.

In recent times, construction quality related issues have been encountered for Teeroff beams, leading to doubts being raised about the ability of the concrete to properly fill the form. This issue is exacerbated for larger and wider Teeroff beams, especially since for such beams up-to 6 layers of prestressing strands can be present in the bottom flange.

Typically, Teeroff beams are cast by pouring concrete down one web, which then flows through the bottom flange, filling the bottom flange and partially filling the opposite web. Once the concrete partially fills the second web in the afore-said manner, the pouring is transferred to be from the top of the second web. In ideal practice, the concrete being poured should fill the form void space under its own weight and inherent viscous flow. As per industry best practice guidance [1], compaction vibrators should not be used to move the concrete (for example across the width of the bottom flange) as that may lead to segregation of the concrete mix.

For Teeroff beams, while the expectation is that by following the afore mentioned pouring sequence the bottom flange will be satisfactorily fully filled by the concrete, the reality may not always be so. Typically, the deeper the beam and wider the bottom flange, it can intuitively be expected that the ability of the concrete to ‘fill the form void’ in this manner will decrease. For a Teeroff beam, the level of reinforcement congestion afforded by the provision of several layers of prestressing strands in the bottom flange worsens this problem. While the workability of the concrete mix itself plays a part in the process of filling the form void, the shape of the precast beam, including the reinforcement present within, also plays a key role, as discussed above.

If there was a rational basis of predicting the ability of a concrete mix to fill the form void of a precast Teeroff beam, this will aid the designer to avoid section shapes and reinforcement configurations which would result in unsatisfactory construction quality. At present, only prior experience of contractors can inform such decisions, noting that current practice may also involve using non-ideal methods such as the use of compaction vibrators to aid the movement of concrete.

Laboratory-based trial moulds provide a physical method of exploring the form filling ability of concrete. Even though such lab-based investigations may not be able to exactly mimic the conditions encountered at actual construction sites, critical parameters affecting the form filling ability of concrete can potentially be identified through such test pours. Accordingly, a CEED project is ongoing at present, where several test pours of L-shaped moulds, representing one web and the bottom flange of a Teeroff beam section, are planned to be completed. The main geometrical parameters that are being investigated through the foregoing project is the depth of the web and the width of the bottom flange. Pours will be carried out for moulds both with and without longitudinal reinforcement (representing strands) and with and without form vibration (with self-compacting concrete being utilised for the latter).

Even though pouring test moulds provides a physical means of assessing the form filling ability of concrete, the number of such moulds that can be poured is limited, due to budgetary as well as time constraints. As a result of this, it may not be possible to investigate all potential parameters of interest affecting the concrete form filling ability of a particular mould shape. For example, in the case of a Teeroff beam, the amount of longitudinal reinforcement (prestressing strands) present, flange thickness, web thickness, sloped areas of bottom flange, and shear ligatures may also affect the form filling ability, in addition to the web depth and bottom flange width.

However, practically, the effects of all these parameters cannot be fully investigated purely through a physical test programme. Computational methods of modelling concrete flow potentially provide a way forward in this regard, if such methods can be successfully implemented to model and predict the form filling behaviour of concrete. As such, this project proposes to explore the possibility of utilising computational methods to predict the form filling behaviour of concrete in relation to Teeroff beams. The results from the test pours of the ongoing related CEED project will form the basis of this investigation effort.

Objectives and outcomes

The main over-arching objective of the proposed project is to investigate and explore the potential of computational fluid dynamics (CFD) based approaches to be used as a predictive tool to model the concrete flow (under its own weight) within form shapes representative of the webs and bottom flanges of Teeroff beams. More specifically the project aims to:

- Carry out a comprehensive review of the literature to identify numerical (computational) methods that have previously been used to model concrete flow, including within constrained geometries with/without reinforcement.

- Using previously reported computational approaches found through (1) as guidance and focusing on CFD methods, carry out modelling of slump/slump-flow tests that will be carried out as part of the ongoing CEED project. For the modelling, it is anticipated that the software ANSYS Fluent will be used. Specific material properties of the fresh concrete mixes which will be obtained as part of the ongoing CEED project (involving pouring of trial moulds) are planned to be utilised for the foregoing modelling.

- Investigate the ability to computationally model the L-shaped mould pours that are planned to be completed as part of the ongoing CEED project. Whilst ideally the approaches identified and developed in (2) will be utilised for this, different modelling approaches may also be needed. Video and image data of the time history of the respective test pours will form the basis of assessing the ability of the computational model to predict the physically observed behaviour during the test pours. Only the trial pours of the ongoing CEED project that will utilise self-compacting concrete will be used for this investigation (i.e. where no form vibration is applied). This is because the primary objective of the proposed modelling is to assess the capability of computational methods to model the form filling of concrete under its own self weight.

- Carry out a parametric study, based on the modelling approaches developed in (3), to ascertain the effects of several pertinent variables on the ability of self-compacting concrete to fill L-shaped form voids (representative of Teeroff beam sections). For this purpose, it is expected that the geometry of the L-shape (i.e. height, width, thickness, slope of web-bottom flange junction etc) and the level of reinforcement (number of layers and number of strands) will be varied. The parametric study could also consider the effects of the material properties of the concrete (e.g. viscosity) on the predicted behaviour.

Through the work of the proposed project, if it is found that numerical (computational) techniques can satisfactorily predict the behaviour of concrete flow into L-shape form voids, this would enable, in extension, rational decisions to be made efficiently on the suitability of Teeroff beam section shapes and level of reinforcement. Even though the proposed work is limited to self-compacting concrete, the identified relative merits of Teeroff sections in relation to concrete form filling will be valid for vibrated concrete pours as well. The above-described work can also be extended to model the actual Teeroff beam shape and reinforcement (rather than a representative L-shape).

Recognising that computational techniques to model the flow of concrete is a developing and evolving science, even if the main outcome is a computational based method to model concrete flow with practical simulation times, this would be an extremely useful outcome. Even if the accuracy of the predicted behaviour is found to be less than exact, such a simulation tool could still be used as a relative measure to evaluate proposed designs of Teeroff sections in relation to the form filling ability of concrete.

Current status and previous research

For the numerical (computational) modelling of concrete flow, two main approaches have been reported in the literature [2]. These are namely the treatment of fresh concrete as a fluid continuum (i.e. continuous approach) and the consideration of fresh concrete as a collection of discrete parties (i.e. discrete approach). The former is implemented using computational fluid dynamics (CFD) whilst the latter is implemented computationally using the discrete element method (DEM). Whilst it is a simplification of the material, CFD methods are less computationally intensive to implement compared to DEM methods. The suitability of which approach to use is a question of what behaviour scale is of interest, i.e. macro vs particle scale, as well as the problem being investigated, say form filling vs segregation of the concrete mix or particle blocking by reinforcement.

It has been reported that both the above approaches have been able to successfully model the filling ability of concrete [3]. These include modelling of the common concrete characterisation slump test as well as open channel flow (i.e. filling of a long box). CFD approaches have also been used to model scenarios of form filling where reinforcement is present. The modelling of concrete flow into a reinforced beam and wall was reported in [4], while the modelling of a laboratory casting of a large-scale highly reinforced beam was reported in [2]. It should be noted that for these cases the inclusion of reinforcement in the modelling necessitated specialised modelling approaches. Nonetheless, the fresh concrete was still modelled as a fluid continuum in the afore-mentioned examples. Such CFD approaches are expected to form the basis of the proposed study.

Benefits to Main Roads WA

Construction quality related issues that have been encountered in recent times for Teeroff beams have resulted in several beams being rejected resulting in project delays and costs. If a rational assessment on the risk of a proposed design encountering construction issues related to the form filling ability of concrete can be made during the design stage in a practical and timely manner, such delays and costs can be avoided. This would also enable the designer to have more confidence about the constructability of section shapes and reinforcement arrangements they specify. The ability to avoid or discard potentially problematic sections during the design stage itself will ultimately result in improvements in the as-constructed quality of Teeroff beams, which is a beneficial outcome to Main Roads WA as the asset owner of numerous bridges which utilise such beams.

References

[1] Cement Concrete & Aggregates Australia, 2020. Guide to Concrete Construction Part V – Concreting Site Practices Handling & Compaction

[2] Vasilic, K., Gram, A. and Wallevik, J.E., 2019. Numerical simulation of fresh concrete flow: insight and challenges. RILEM Technical Letters, 4, pp.57-66.

[3] Roussel, N., Gram, A., Cremonesi, M., Ferrara, L., Krenzer, K., Mechtcherine, V., Shyshko, S., Skocec, J., Spangenberg, J., Svec, O. and Thrane, L.N., 2016. Numerical simulations of concrete flow: A benchmark comparison. Cement and Concrete Research, 79, pp.265-271.

[4] Roussel, N., Geiker, M.R., Dufour, F., Thrane, L.N. and Szabo, P., 2007. Computational modeling of concrete flow: General overview. Cement and Concrete research, 37(9), pp.1298-1307.

PROJECT NUMBER: 25/003

PROJECT TITLE: Computational modelling of form filling of concrete

CLIENT: Main Roads WA

DISCIPLINE: Civil, Chemical or Mechanical Engineering (Note: the student should either have completed or will enrol in semester 2, Transport Phenomena CHPR4407)

SUPERVISOR: Dr Jeremy Leggoe

PROJECT TYPE: Full – Student must be able to attend 8 weeks site work with client over the university break. 450 hours credit will be given toward Professional Practicum hours.

STUDENTSHIP: $10,000

DEADLINE: Sunday 12th May, 2024